Trussless arch roofing has brought a revolutionary change in Kerala’s construction industry. This innovation is an American expertise proven and applied in over 60 countries over the last 30 years. Its durability, design efficiency, and cost-effectiveness are some factors that make it an unavoidable part of an industry. Apart from the traditional roofing methods, These self-supported roofs reduce the need for trusses, enabling broader spans without affecting stability. This makes them best for warehouses, industrial units, sports complexes, etc. The spaces can be used efficiently with visual beauty. In an all-steel construction, the flat panels can also be utilized for side-wall and gable-end cladding.

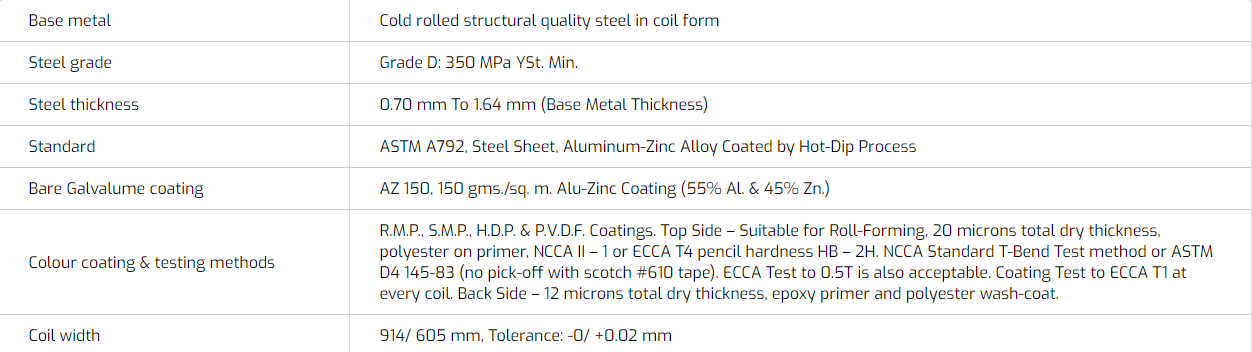

Modern trussless roofs utilize advanced engineering techniques, including computer-aided design (CAD) software, ensuring that roofs meet safety standards against wind, seismic activity, and other environmental stresses. The panels used for arch roofing require no trusses, purlins, or ancillary supports for up to a length of up to 36 meters. This system uses eco-friendly materials along with the rising trend of trussless arch roofing construction in Kerala. These roofing and cladding panels are manufactured from high-quality, structural-grade steel using advanced technologies. Skylights, ventilators, and modular panels are used to enhance efficiency and effectiveness.

The cost of trussless arch roofing in Kerala differs based on the materials used, design complexity, and the scale of the project. Customizations, the use of imported materials, and additional features such as thermal insulation or soundproofing are some of the features that can also influence the price. We Proarch, provide tailored trussless archroofing solutions, that cater to both budget-conscious and premium segments. Contact us to get a rough idea about the expense.

Proarch Roofings is designed to suit more than 20 different Building Codes from all around the world, of which, a few recognized ones are listed below:

Proarch Engineering uses specialized Design & Engineering software to do a calculative study of Proarch roofing. According to ASCE 7-02, the International Building Code 2002, and BIS, this program factors the load parameters. The technology provider's design software has handled parameters such as cyclones, earthquakes, wind speeds, live loads, etc., and data has been input in accordance with the current IS requirements in that area. The maximum wind speed in each zone is taken into account while designing roofs as per the National Building Code. The design takes into account a safety factor of 1.8 times. This provides sufficient resistance to uplift forces produced by gusts of wind.

Taking into account the necessary live load, wind load, dead load, and seismic component, the analysis is performed for the specified span and central arch-rise. This study establishes the arch responses at the beam level as well as the steel thickness. Our consulting engineer then uses this information to design the building's beams, columns, and foundations. Based on the bolts' and the steel's uplift and shear capabilities, the number of fasteners or bolts per end of the panel is decided. This unique design and engineering software saves a significant amount of time and money when choosing the most cost-effective arch structure arrangement. The program modules will guide the designer through the examination of the arch structure in a methodical, menu-driven process. In contrast to traditional design processes, which could have taken two to three weeks, an arch structure can be designed in roughly five minutes using our Design & Engineering software.

It should be mentioned that the consulting engineer will use the structural data derived from this analysis to build the necessary structure and determine whether it is stable enough to support the loads coming from the roof.

Investing in high-quality arch roofing is cost-effective in the long run due to its low maintenance and high durability. With Kerala’s focus on modern infrastructure and sustainable practices, arch roofing has become a popular choice for both residential and commercial constructions. This technology's seamless blend of form and function ensures that it remains a top contender in Kerala’s evolving architectural landscape. For a detailed consultation or project-specific estimates, contact us.

For reliable and cost-effective trussless arch roofing solutions, contact Proarch Engineering today. We have professionals who can assist you in designing and installing the perfect trussless roofing system for you.